Manage tools digitally with twinio

Tool management can be so simple

Discover twinio's flexible tool management options.

Keep an overview

Easily keep track of the storage location, condition and availability of an unlimited number of tools and tool holders.

Manufacturer's

tooldata

Tools with original tool data directly from various manufacturers digitally available in the web app.

Manufacturer's

tooldata

Tools with original tool data directly from various manufacturers digitally available in the web app.

Tool performance

View and evaluate tool performance using historical data.

Tool performance

View and evaluate tool performance using historical data.

Easy and free creation

Create any tool manually by yourself. Alternatively, you can use twinio Scanning to add a tool with just one scan.

Easy and free creation

Create any tool manually by yourself. Alternatively, you can use twinio Scanning to add a tool with just one scan.

Overview

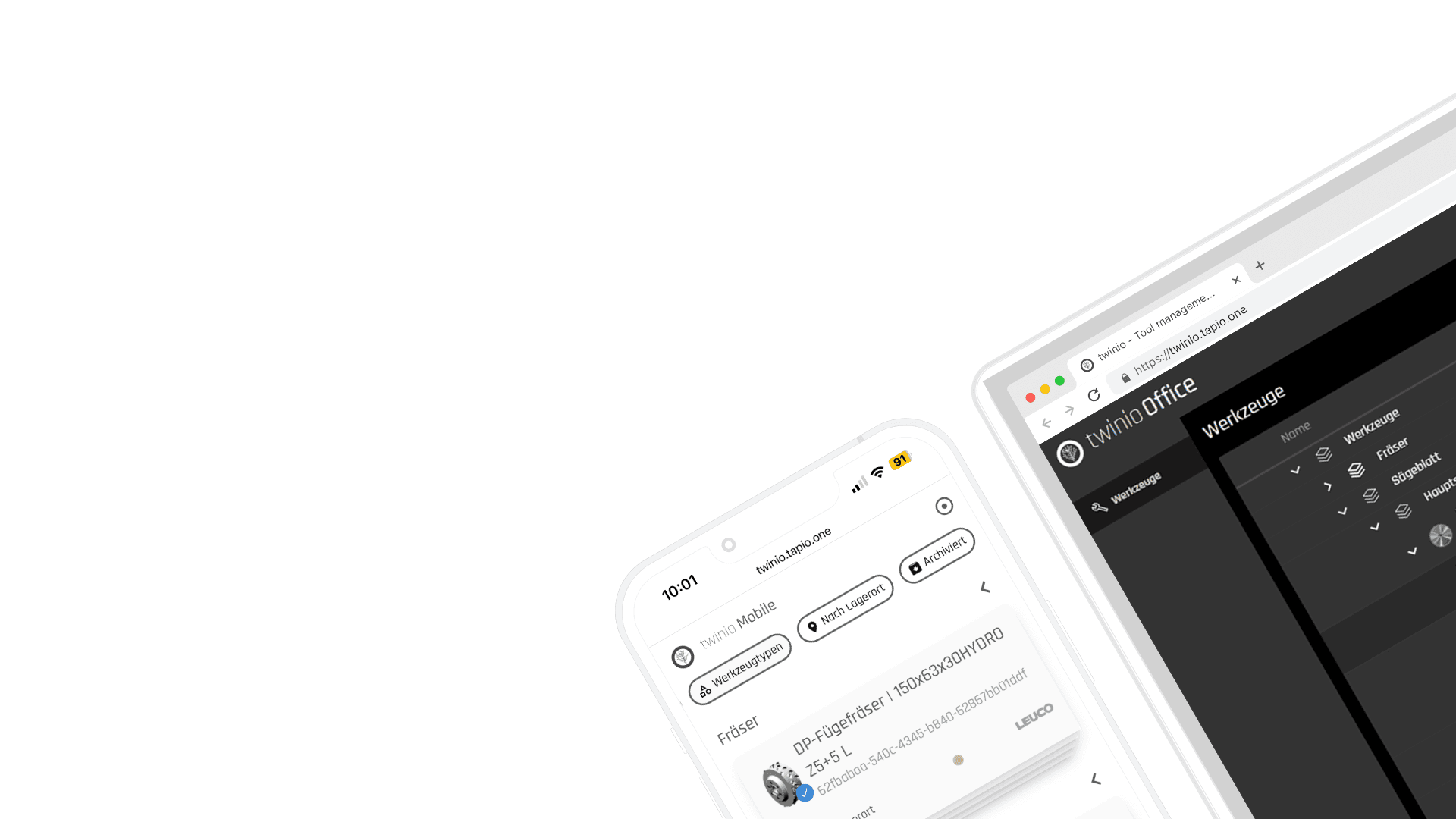

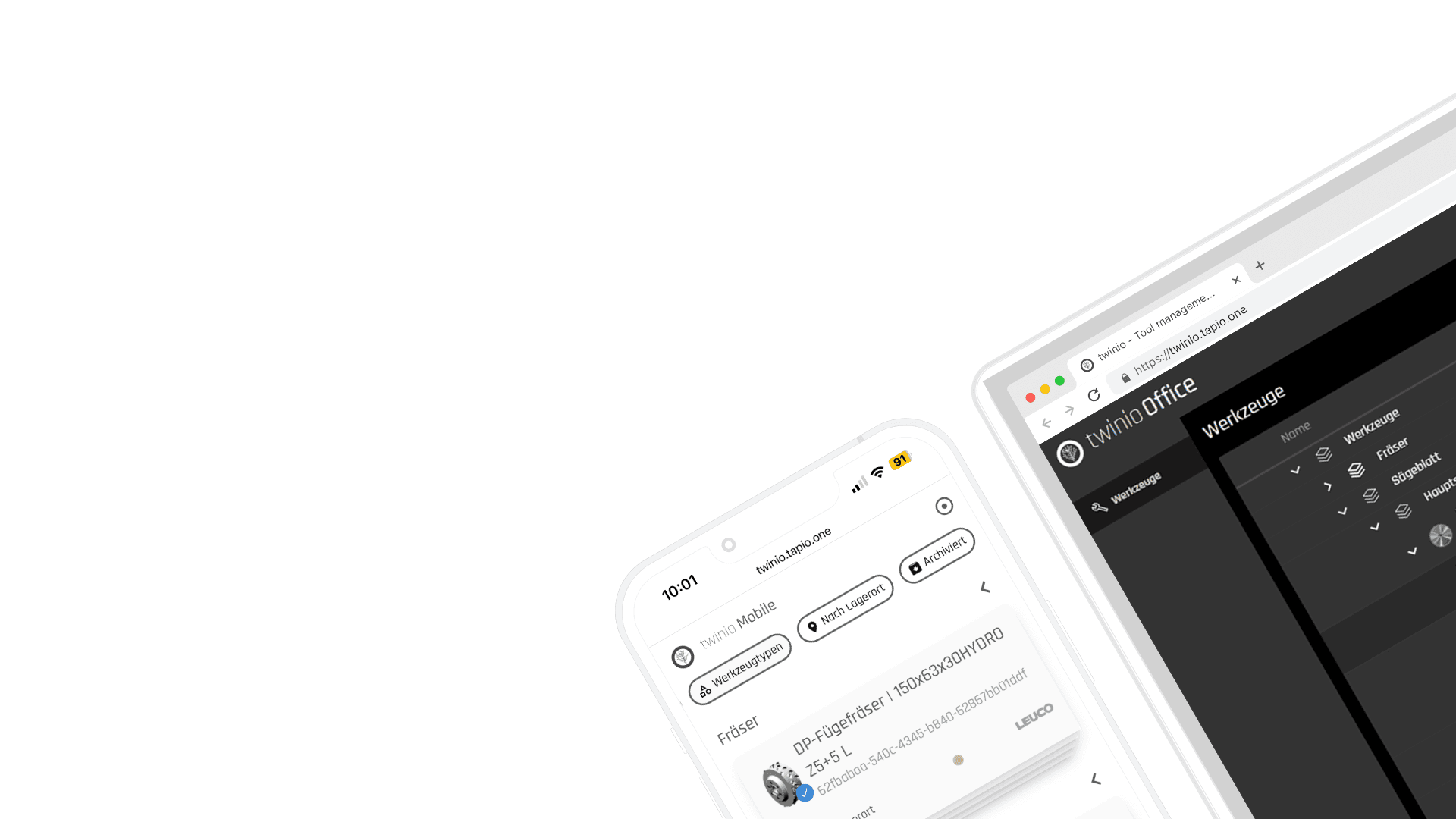

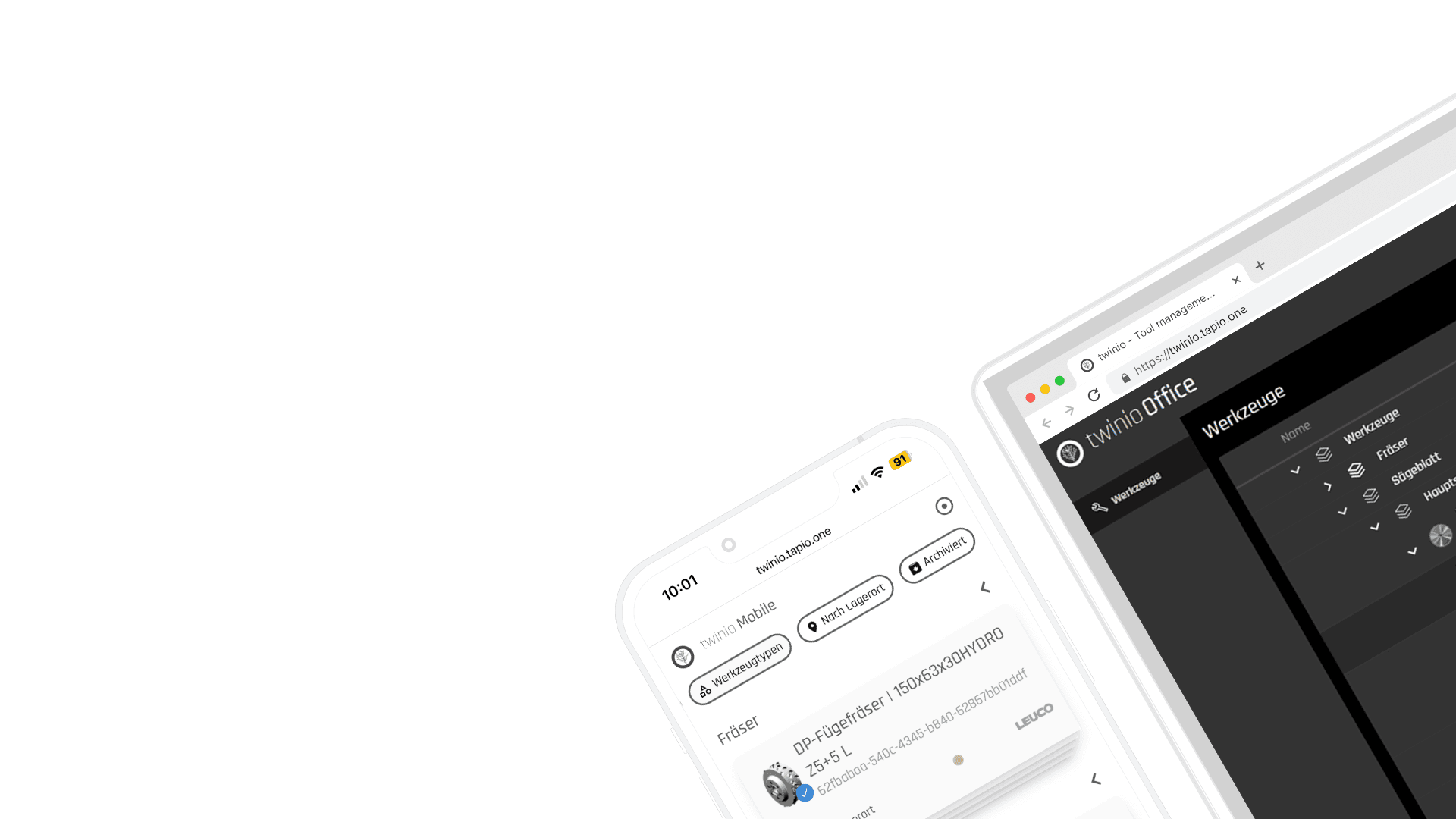

Easily keep an eye on tools

With twinio, you can keep an eye on your tools - whether on your smartphone or desktop. Find every tool quickly and easily, regardless of storage location or machine. twinio offers location-independent management for efficient use of your time. Use the user-friendly interface and experience the future of digital tool tracking.

Overview

Easily keep an eye on tools

With twinio, you can keep an eye on your tools - whether on your smartphone or desktop. Find every tool quickly and easily, regardless of storage location or machine. twinio offers location-independent management for efficient use of your time. Use the user-friendly interface and experience the future of digital tool tracking.

Overview

Easily keep an eye on tools

With twinio, you can keep an eye on your tools - whether on your smartphone or desktop. Find every tool quickly and easily, regardless of storage location or machine. twinio offers location-independent management for efficient use of your time. Use the user-friendly interface and experience the future of digital tool tracking.

Complete freedom from

from the very first moment!

Scan tools

Lightning fast: Scan manufacturer IDs and get started

Save time with the premium data package by scanning the manufacturer IDs of your tools and creating digital twins in seconds. Avoid errors by uniquely identifying tools throughout their lifecycle using the specific manufacturer ID.

Scan tools

Lightning fast: Scan manufacturer IDs and get started

Save time with the premium data package by scanning the manufacturer IDs of your tools and creating digital twins in seconds. Avoid errors by uniquely identifying tools throughout their lifecycle using the specific manufacturer ID.

Scan tools

Lightning fast: Scan manufacturer IDs and get started

Save time with the premium data package by scanning the manufacturer IDs of your tools and creating digital twins in seconds. Avoid errors by uniquely identifying tools throughout their lifecycle using the specific manufacturer ID.

Manually Create

Create unlimited tools

With twinio Basic, you can manually create and manage an unlimited number of tools in just 6 steps. Access databases from various tool manufacturers or create your own tools from scratch. Including digital tool cards for comprehensive management - all included in the basic license.

Manually Create

Create unlimited tools

With twinio Basic, you can manually create and manage an unlimited number of tools in just 6 steps. Access databases from various tool manufacturers or create your own tools from scratch. Including digital tool cards for comprehensive management - all included in the basic license.

Manually Create

Create unlimited tools

With twinio Basic, you can manually create and manage an unlimited number of tools in just 6 steps. Access databases from various tool manufacturers or create your own tools from scratch. Including digital tool cards for comprehensive management - all included in the basic license.

Tool partner

Retrieve tools from tapio partners via scan

Prices

Prices

Prices

Choose the right

package for your

tool management

Basic

Yearly

7.50

€

Per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Basic

Yearly

7.50

€

Per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Basic

Yearly

7.50

€

Per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Basic + Scanning

Yearly

11.67

€

Per tool partner / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Basic + Scanning

Yearly

11.67

€

Per tool partner / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Basic + Scanning

Yearly

11.67

€

Per tool partner / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Basic + Sharpening

Yearly

15.00

€

Per sharpening service / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Create and track sharpening orders

Basic + Sharpening

Yearly

15.00

€

Per sharpening service / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Create and track sharpening orders

Basic + Sharpening

Yearly

15.00

€

Per sharpening service / per month

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Create and track sharpening orders

Plus Scanning + Sharpening

Yearly

19.17

€

For sharpening service & tool partner

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Create and track sharpening orders

Plus Scanning + Sharpening

Yearly

19.17

€

For sharpening service & tool partner

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Create and track sharpening orders

Plus Scanning + Sharpening

Yearly

19.17

€

For sharpening service & tool partner

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data manually

Scan unique manufacturer IDs & uniquely identify

Create and track sharpening orders

Connect

Lets talk!

One-time costs per machine on request

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data automatically

Machine connectivity with selected machine

Automatic transfer of tool data to the machine

Access to the cloud-based tool database of the machine

Connect

Lets talk!

One-time costs per machine on request

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data automatically

Machine connectivity with selected machine

Automatic transfer of tool data to the machine

Access to the cloud-based tool database of the machine

Connect

Lets talk!

One-time costs per machine on request

Unlimited number of users

Unlimited number of tools

Custom QR codes

Capture process data automatically

Machine connectivity with selected machine

Automatic transfer of tool data to the machine

Access to the cloud-based tool database of the machine

FAQ

How do I get twinio on my smartphone?

How do I get twinio on my smartphone?

How do I get twinio on my smartphone?

How do I add tools and recordings to twinio Mobile?

How do I add tools and recordings to twinio Mobile?

How do I add tools and recordings to twinio Mobile?

How do I change the location of a tool in twinio Mobile?

How do I change the location of a tool in twinio Mobile?

How do I change the location of a tool in twinio Mobile?

How do I set limit values for my tool in twinio Mobile?

How do I set limit values for my tool in twinio Mobile?

How do I set limit values for my tool in twinio Mobile?

How do I manually sharpen tools in twinio Mobile?

How do I manually sharpen tools in twinio Mobile?

How do I manually sharpen tools in twinio Mobile?

How do I create a QR code for my tool?

How do I create a QR code for my tool?

How do I create a QR code for my tool?

How do I connect tools and adapters in twinio Mobile?

How do I connect tools and adapters in twinio Mobile?

How do I connect tools and adapters in twinio Mobile?

More questions?

Matching solutions

materialManager

Manage material digitally

materialManager

Manage material digitally

materialManager

Manage material digitally

productionManager

Digital job folder

productionManager

Digital job folder

productionManager

Digital job folder

ServiceBoard

Remote and digital machine service

ServiceBoard

Remote and digital machine service

ServiceBoard

Remote and digital machine service

Get started now

Get started now

With the tool management of tapio

With the tool management of tapio

No My tapio company account yet?

No My tapio company account yet?

No My tapio company account yet?